Newsletter

M7 Wave Table

Environmentally Safer to Use:

- No chemicals needed

- Uses recycled water

- Recovers float material

- No waste disposal costs

- Safer for employees to operate

- Actually recovers mercury from ores & tailing piles

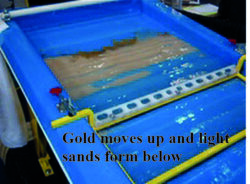

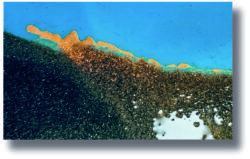

How It Works: The pictures show the results of the wave theory of the table. Separating by specific gravity, the sand forms in drifts directly under the standing wave of water. Even light blond sand forms drifts, not washing away.

Due to the Standing Wave principle, the heaviest particles remain through the low motion area of the Standing Wave. The wave itself moves; the water directly beneath the wave tends to stand still. The further from the top of the wave, the less motion is in the water. Thus, the heavier the particle the deeper it will ride and the less motion it will see. The “Riffle weir bar” assists in dropping ‘float gold’ to the table surface, enabling a faster production run without fear of losing gold or other metals that normally would be lost on most tables.

In view of the fact that the table top moves back and forth, the micron particles of heavy material (gold, PGMs, scheelite, copper, zinc oxide, etc.) sink to the bottom under the wave. The finer particles (-600 mesh and smaller) drop into a Skin Effect area. That area is directly against the skin of the table top. The water in this area does not move with the flowing water but rather sits almost still. The motion of the table causes this “Skin Effect” water to move in the opposite direction of the flow.

Thus the fine gold or heavy material moves ‘up’ the table and falls into the concentrate trough. The gold and/or concentrates can then be washed automatically into a concentrate bucket or a security safe, or vacuumed off the table. Ore should be classified according to size for efficient results.

Micron Mill Wave Table M7/8/9 – rated 1 tph of classified head ore

Price $15,295.00 usd

(crating in the USA is $250.00 & overseas is $350.00)

Shipping and handling is charged separately. Call 1 .406.826.9330 or 1.800.624.1511 for shipping quote today!

M7 110V 60C, IP55

M8 220V, 50C, IP55

M9 220V, 60C, IP55

Catalog available & spec sheet click here: m7_8_9 SPEC SHEET 2023

While having the capability of acting as a production table for a smaller mill or pilot operation, the M7 can be used as a Finish Table producing a very high grade concentrate of precious metals; or even used in a lab for small samples without loss in efficiency. Gold will separate at a high percentage from black sands – which is a statement unheard of in mechanical separation considering the specific gravity of black sands and gold are so close in proximity!

Run 20-2000 pounds of head ore material per hour, depending on the material with recovery of particles ranging between 10 mesh and microscopic; recovery of gold from classified black sand ranges from 80% to 99%; recovery of gold from small batches of classified black sands ranges from 92% to 99%.

Water requirements are 5 to 12 GPM, with 2 adjustable water spray bars; power 1/2 HP 50/60C class F motor, IP55, 110/220V depending on customer requirements; steel frame construction is finished yellow with high corrosion-resistant baked-on, powder coat epoxy paint; table top and hopper are constructed of fiberglass gel- coated in finish blue to easily gravity feed from a slurry tank, trommel, chute, pipe, etc.; adjustable table top tilt & “bump”; equipped with variable speed control unit.

Action Mining Services Inc. Copyright © 2023 All rights reserved www.actionmining.com